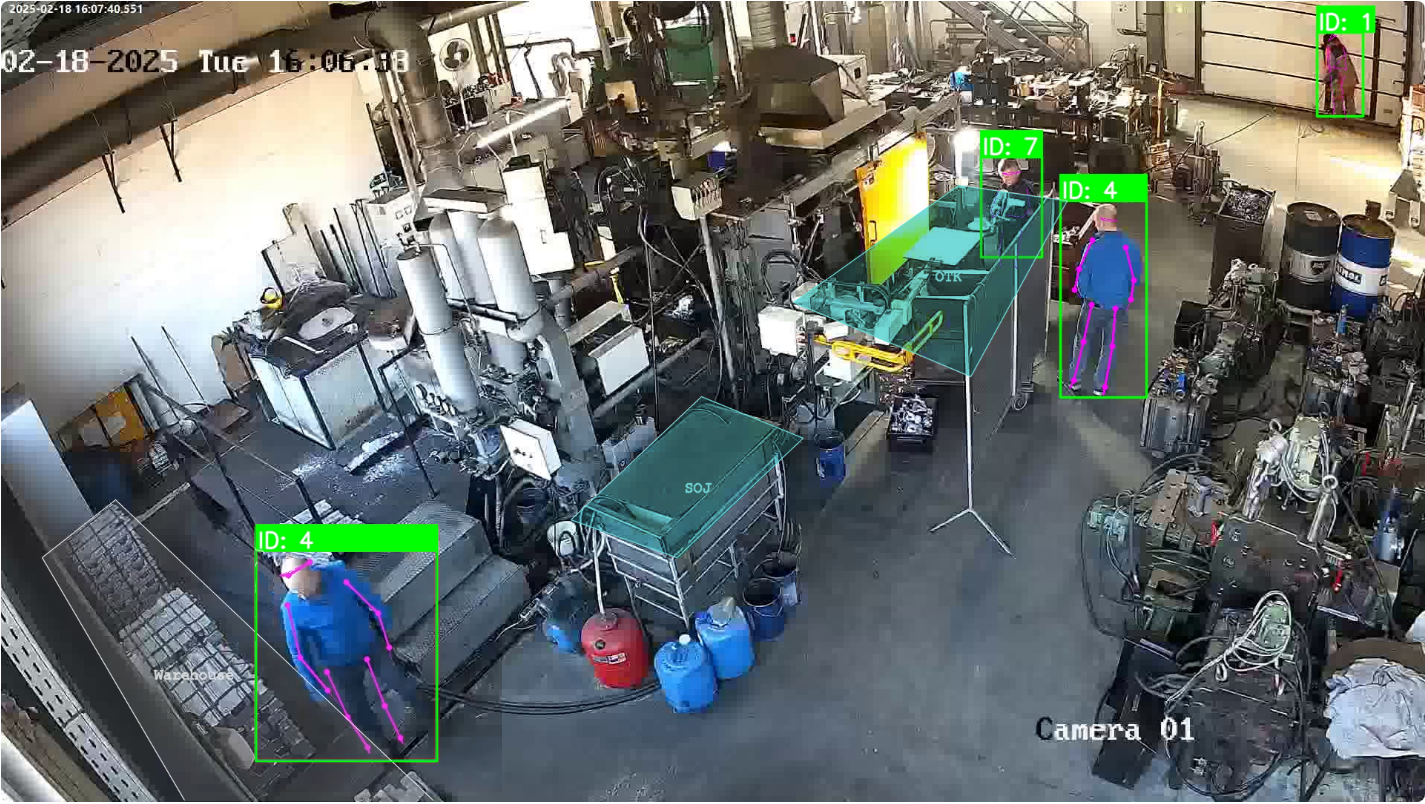

In high-precision industries like casting, skipping just one process step can lead to defective parts, wasted materials, and significant $$$ losses. While human monitoring is essential, it’s also expensive and prone to errors. That’s where video analytics comes in! Our tests of 3DiVi Omni Analytics in a casting plant showed how it can efficiently monitor critical processes and prevent human error. Here’s what it can track:

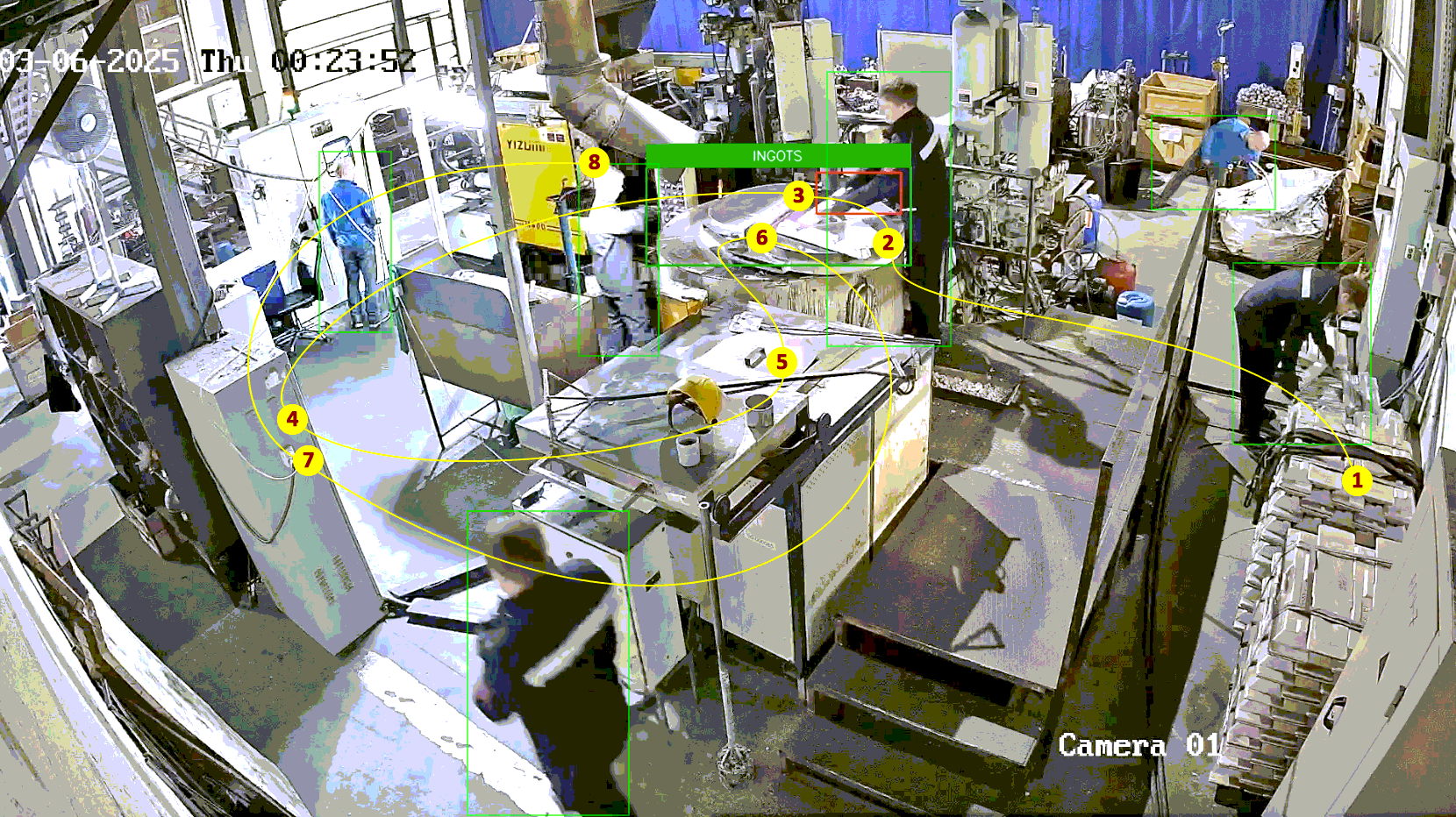

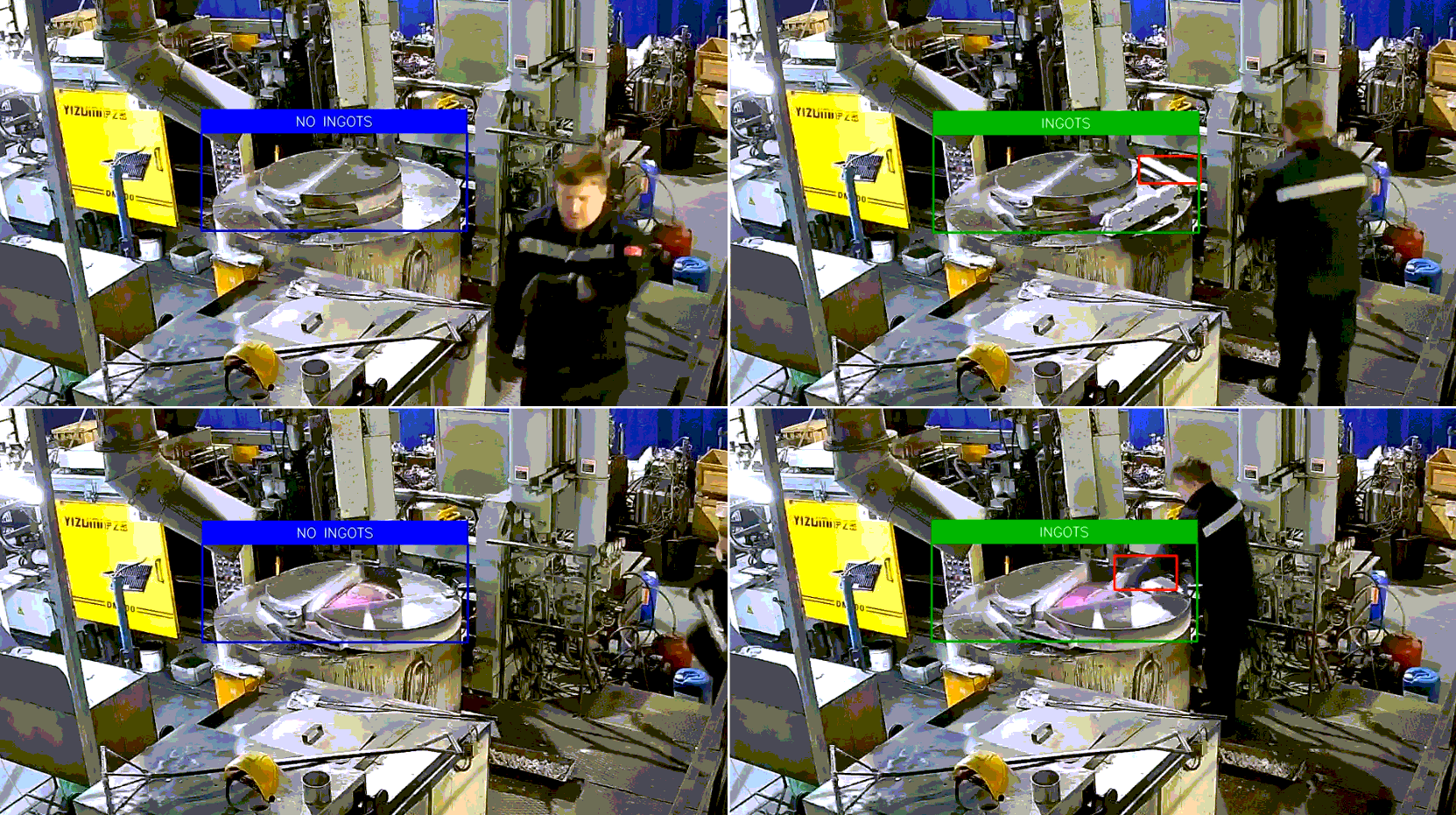

Raw material handling

Video analytics monitors employee interactions with storage zones, ensuring they follow the correct sequence for metal ingots and chemical additives.

For instance, before loading ingots into the crucible, it’s essential to preheat them. It not only prevents excessive cooling in the crucible, but avoids dangerous water vapor explosions during casting, which can lead to unwanted bubbles in the alloy.

Video analytics also keeps an eye on the order of chemical additives—The process starts with adding the ingots, then adjusting the temperature in the heating zone to 730°C. Once it reaches the target temperature, the first chemical—a flux—is added, then the slag is removed. Next, the degasser is added to release any trapped gases. Once the temperature drops to 650°C, casting can start.

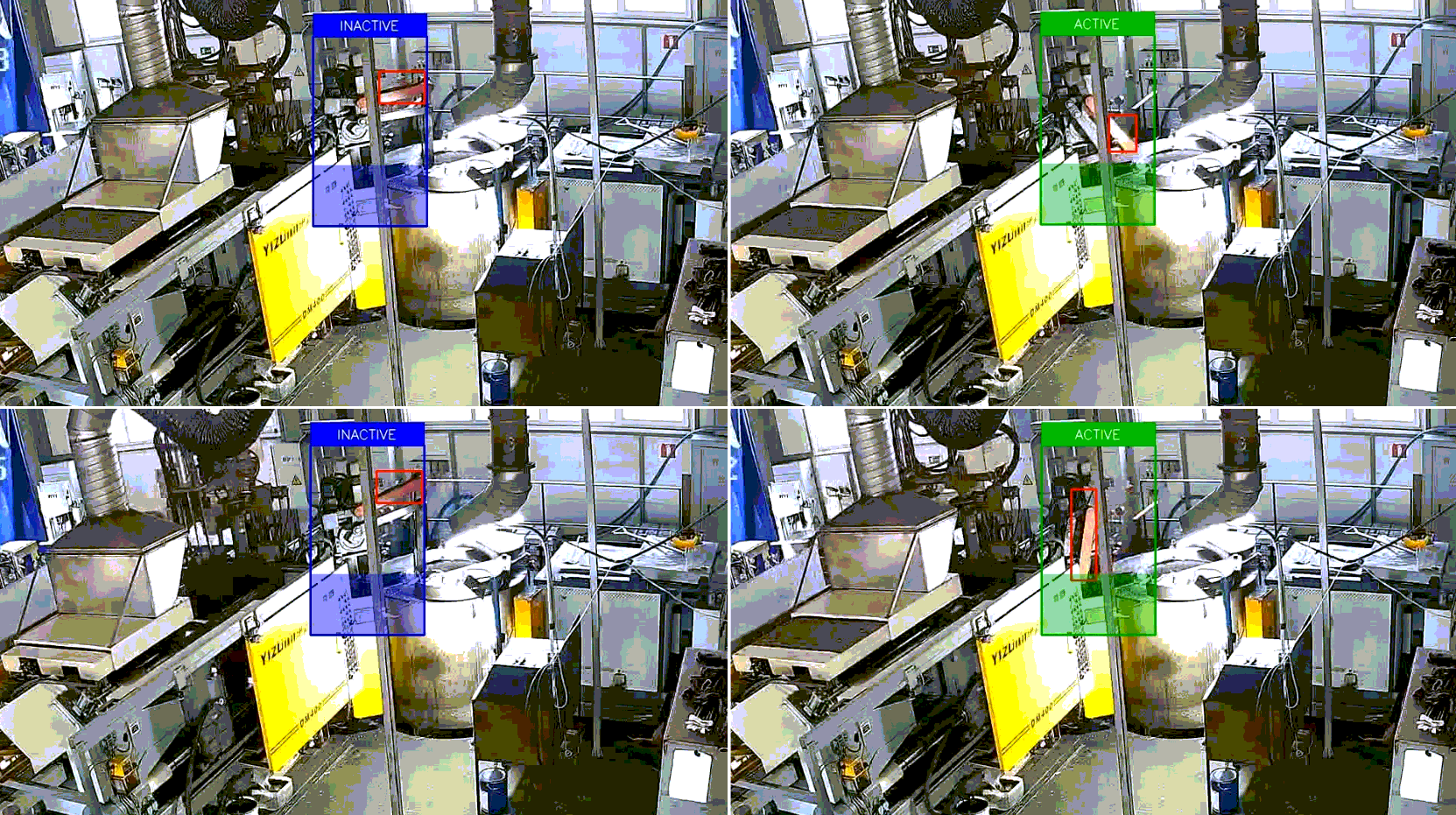

Monitoring casting inspections

After each casting cycle, employees must inspect the castings for potential defects from the mold, such as scratches or marks. Early detection is crucial—if defects are found, casting must be paused to prevent damage to both the alloy and the mold. This helps avoid costly repairs or mold replacements down the line.

Product detection in specific zones

One of the standout features of 3DiVi Omni Analytics is its ability to adapt to detecting specific objects using few-shot learning. In our testing, the system quickly learned to detect ingots in the preheating zone and monitor metal flow for injection.

In a field where small oversights can lead to costly mistakes, 3DiVi Omni Analytics is already helping manufacturers ensure every operation runs smoothly. Looking to upgrade your process monitoring? Let’s discuss how video analytics can help.